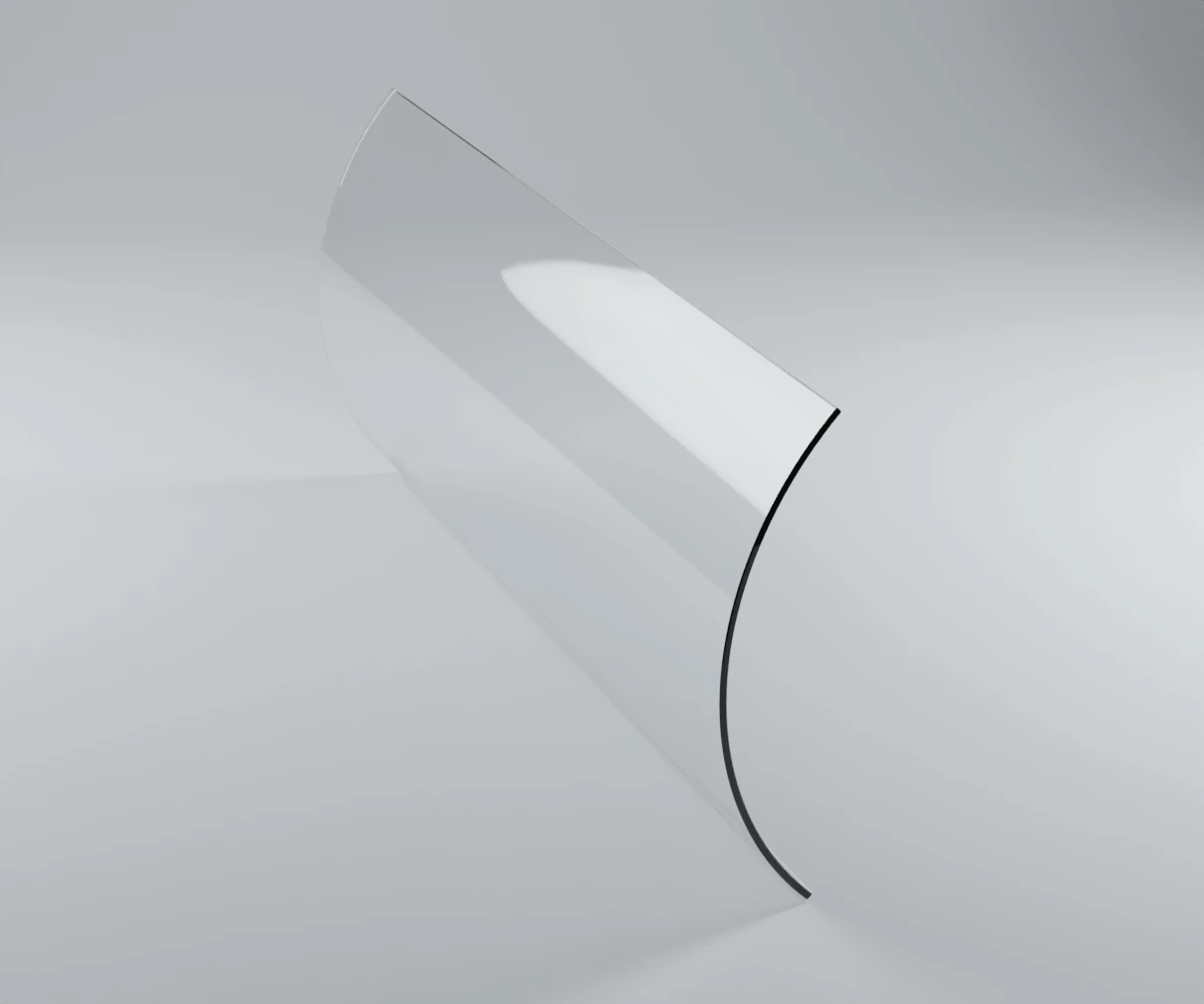

Bent toughened glass

Building glass is mainly associated with flat surfaces of facades, partition walls and other interior design elements. However, it also has another aspect which makes it three-dimensional owing to bending.

Bent glass units offered by PRESS GLASS are made in a process based on tempering. After reaching the glass temperature close to the softening point, the glass pane is curved to obtain the required shape and then quickly cooled down, i.e. tempered. The process of bending provides glass with a new functional and aesthetic quality.

Market offer

PRESS GLASS offers single glazed units and glazed units, cylindrically bent glass panes based on monolithic float glass, non-coated or with thermal insulating and solar control coatings, tinted or laminated glass.

To make a product more attractive and to extend the range of its application, bent glass can be covered with screen print or digital print according to standard patterns or individual designs.

| Type of bending | Glass thickness [mm] |

Minimum panel dimensions [mm] |

Maximum panel dimensions [mm] |

Minimum bending radius [mm] |

| CB |

6-8 float 10 float 12-15 float |

750 x 750 |

2400(2) x 4200 2400(2) x 4200 2400(2) x 4200 |

15001 30001 40001 |

| LB |

5 float 6-10 float 12-15 float |

500(2) x 200 |

3600(2) x 2200 4200(2) x 2400 4200(2) x 2400 |

25001 25001 40001 |

1 depends on the size and shape

2 the bending edge

LB – glass bending along a longer edge

CB – glass bending along a shorter edge

Glass bending/curving direction:

LB – glass bending along a longer edge

CB – glass bending along a shorter edge

Video of the process

See how glass is bent for large façade glazing. The process is carried out at the Press Glass production plant in Tychy.

Vaghuset Business Center, Stockholm, Sweden

Sawig Office, Cracow, Poland

125 Greenwich Street, New York, USA

Press Glass Headquarters, Konopiska, Poland

SPECIFICATIONS AND ADVANTAGES OF CURVED GLASS

The offer of curved toughened glass includes:

- monolithic and laminated glass as well as double and triple glazed units,

- rectangular glass, catalogue shapes and CAD CAM shapes,

- glass with ground, polished and bevelled edges,

- glass with drill holes and cut outs / notches,

- printed glass (digital print, screen print, full enamel coating)*

* enamel and coating only on the concave side

Declarations of performance

The ETA (European Technical Assessment) issued for Press Glass certifies that it is now the only company in Europe authorised to issue a declaration of performance for cylindrically curved toughened and laminated glass in accordance with the Construction Products Regulation (CPR). This unique achievement allows PRESS GLASS to stamp its curved products and paperwork with the European CE mark for this group of products, confirming both their high quality and their compliance with the highest safety standards.

Advantages of curved glass

- increases the visual attractiveness of the building facade,

- modern and elegant design,

- allows the creation of non-standard forms, increases design possibilities.

Thanks to the toughening process, it gains all advantages of toughened glass, i.e.:

- greater mechanical strength,

- resistance to thermal shock breakage,

- safety glass classification,

- safe breakage characteristic.

Application of curved glass

Curved toughened glass is always produced to individual order, which is verified for technical / production feasibility. Curved glass offered by Press Glass can be used in:

- Facades: as glazing to the external envelope of the building, skylights, doors, structural balustrading and balustrading infills including balconies and stairwells.

- Interior glazing: framed and structural partition walls, doors, stairwells, glass furniture and decoration.

3D GLASS

3D GLASS is a revolutionary, patented technology that lets you shape three-dimensional, smoothly changing glass surfaces and facades. Check out the details of 3D glass on the designated website.

Reference projects with 3D Glass from Press Glass

We constantly modify our manufacturing processes and change habits to limit the negative effect on the environment.

In order to facilitate the changes, we have adopted ISO 14001, the worldwide management system for environmental protection.